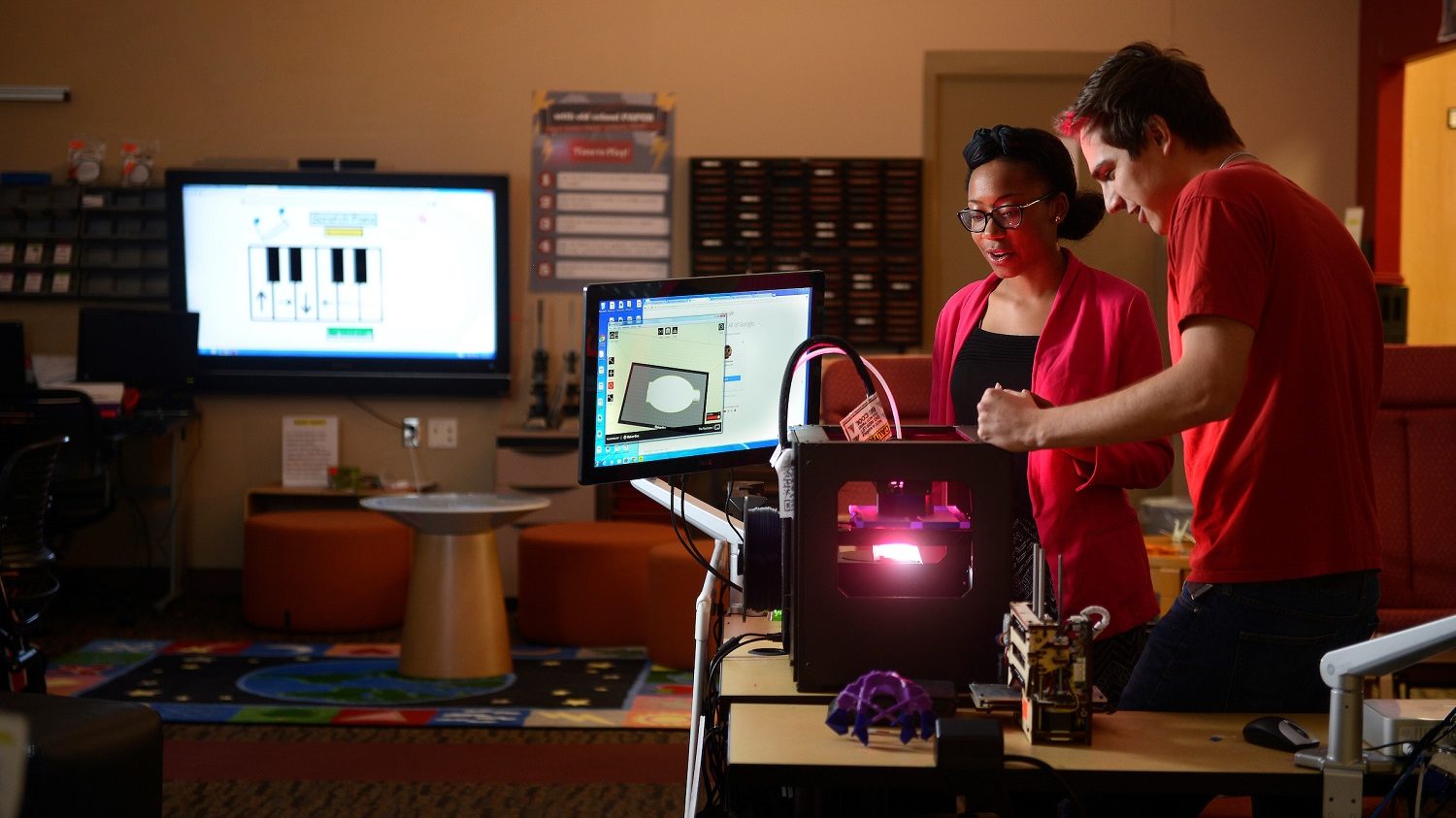

The Quest to Find Sustainable Materials for 3D Printing

Photo by Marc Hall

By Rejaul Hasan, BSC Associate, Ph.D. Candidate, College of Textiles

Contributors:

Dr. Jesse S. Jur, Assistant Professor, College of Textiles

Dr. Richard Venditti, Professor, College of Natural Resources

Alexa Kearns, Graduate Research Assistant, College of Textiles

In the continuous search for novel manufacturing techniques, 3D printing (Additive Manufacturing) has gained momentum as a viable option. 3D printing is the process of joining materials to make objects from 3D model data, usually layer upon layer. 3D printing technologies have been around since the 1980s but it is only in the past decade that discussion about their disruptive potential has sped up.

Ernst & Young GmbH’s 2016 Global 3D printing Report mentioned that in a chosen sample of leading companies, 24% have already gained 3D printing experience and an additional 12 % are intending to do so. 38% of the surveyed companies believe they will use 3D printing in their production within five years. Manufacturers across a broad spectrum of industries including automotive, aerospace, dental, discrete, high tech, and medical are all actively piloting and using 3D printing technologies today.

Wohler’s Report for 2014 mentioned the worldwide 3D printing industry is now expected to grow from $3.07B in revenue in 2013 to $12.8B by 2018, and exceed $21B in worldwide revenue by 2020. Understanding the different types of filaments and resins that can be incorporated into 3D printing will be vital in establishing the realm of this emerging field.

A quest is underway to find sustainable materials for 3D printing by a group of North Carolina State University (NC State) researchers from the College of Textiles and College of Natural Resources in association with Cotton Inc. This team has attempted to develop a novel plastic material from Poly(lactic)acid (PLA) and Recycled cotton using Fused Deposition Modeling (FDM). Poly(lactic)acid (PLA) is an easily processed thermoplastic with high strength and biocompatibility, and biodegradable properties.

Cotton, a cellulose fiber, is a good heat conductor, allowing for more uniform heating and melting throughout the filament. Cotton has desirable properties over other cellulose materials because it has a higher aspect ratio due to the size of the fiber. The cotton fibers used in this research were developed from recycled t-shirts, bleached, ground into microfibers, and dried.

The research showed that cotton can be incorporated into a PLA based filament at varying weight percentages and printed into dog bone and compression printed shapes. A full profile mechanical testing of the developed 3D printed material demonstrated up to the mark tensile, compression and the other performance for a wide range of functional use.

The use of recycled cotton which is biodegradable and has been diverted from landfills was an important achievement from a sustainability point of view.

As per EPA, every year 14 million tons of cloth go into USA landfills which averages 80 pounds per person; a large part of this cloth is made of cotton. This research demonstrates the high potentiality of diverting cloth from landfills to create a useful plastic which will then be used as a raw material for 3D printing. This is a great way for fast fashion using the modern technology to address the challenge of excess landfill material.

- Categories: