GREENSBORO TEXTILE COMPANY RESCUES MILLIONS OF BOTTLES FROM LANDFILL

Image: REPREVE

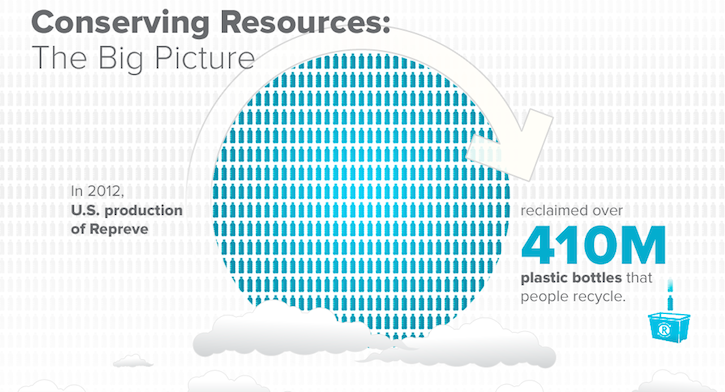

Greensboro-based Unifi is helping to green America’s textile industry. At the company’s REPREVE Recycling Center in Yadkinville, materials that otherwise might have ended up in a landfill are spun into high quality polyester and nylon yarn. Millions of used plastic bottles arrive at the factory each year to be washed and broken down into polymer chips. Unifi and its partners in the textile industry use these chips in the production of synthetic fibers.

Recycling scrap fibers

Unifi is also working with other textile manufacturers to recycle scrap fibers and yarns. In garment manufacturing, 8-15% of fabric typically ends up as cut waste, too small to be used for anything. Now these scraps can be sent to Yadkinville and receive a second life as fabric. The REPREVE Textile Takeback Program reclaims various polyester based fabrics, spinning them back into thread that can be used in production.

The first decade of the millennium was hard on the US textile industry, due to increased competition oversees and a sluggish economy. But thanks in large part to the REPREVE brand recycled fibers, Unifi is now expanding production and putting more North Carolinians back to work in textile. The last few years have seen growing demand for recycled yarn, made in the US. Unifi is partnering with textile factories across the continent to create eco-friendly brands. Millions of plastic bottles are working their way into products like Patagonia jackets and the fabric inside Ford’s Focus Electric cars.

Competing with commodified yarns

Growing concern over the labor and environmental practices of some textile manufacturers has consumers waking up to the fact that not all fiber is created equal. Unifi hopes to differentiate its products from the commodified look-alike, made in less ecologically and socially responsible ways. Last year, the REPREVE product line became the first synthetic fabric line to earn a “Responsible Source” certification from SCS Global Services.

Shaping international trade policy

As head of the National Council of Textile Organizations, Unifi CEO William Jasper has worked hard to represent the US textile industry’s interests in Washington for the past three years. He has been instrumental in closing a loophole in the proposed Trans-Pacific Partnership (TPP) agreement that would have shifted regulatory focus from the yarn producer, to the textile manufacturer. This would have made the inputs into textile production more of a commodity, making it harder for yarn-producers to differentiate their products. The loophole would have allowed Vietnamese textile manufacturers to start using Chinese-made yarn, while still benefiting from the tariff-free trade arrangement that “Made in Vietnam” products would enjoy under the TPP.

From slaves picking cotton to children working in sweatshops, activists have identified numerous social and environmental issues with low-cost textile products. Unifi hopes that consumers are ready to vote with their wallets and embrace a fair and sustainable future for textile production.