BUILD LOCAL: IN SEARCH OF BIOREGIONAL CONSTRUCTION

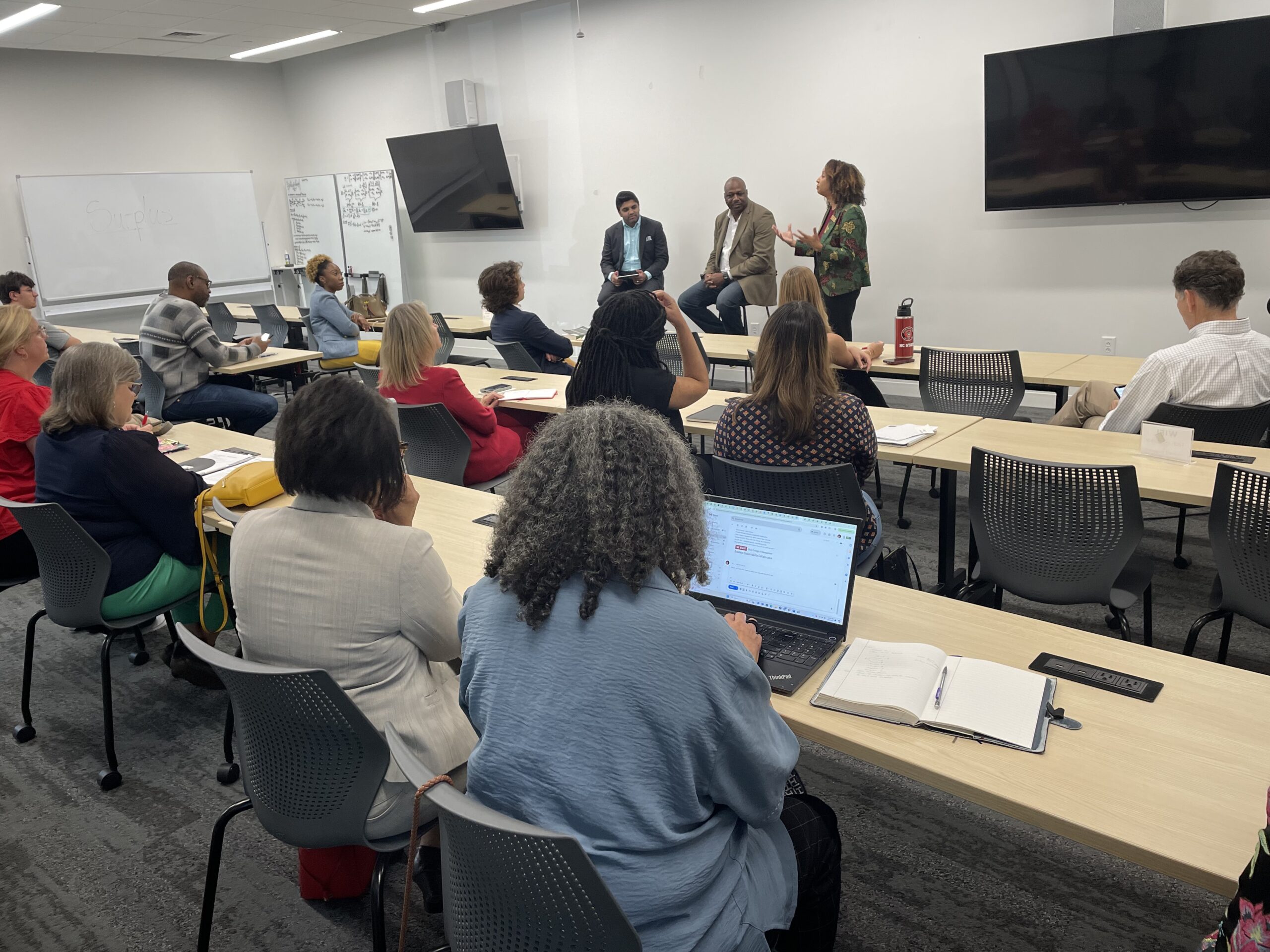

Photo: DIG Southeast

Conversations about green building often focus on building performance – energy use, water use, comfort. Increasingly, however, the industry is also beginning to focus on the embodied energy, resource use and waste involved in the actual construction of a building. One company – DIG Southeast – is well placed to capitalize on this shift, producing “bricks” (technically Compressed Earth Blocks) that are local, biodegradable and have a low embodied energy. They are the product of a vision brought to life by Jeff Gannon of Green Door Design/Build in Pittsboro, North Carolina.

“The thing I love about CEB is that it is a truly local and sustainable building material; the carbon footprint is as low as it gets, beginning with the fact that we don’t ever use topsoil, just subsoil. Plus we are able to process blocks in a very low fuel consumptive way, and the end products is an aesthetically flexible block. It feels good, it looks good, it’s strong, and it has unlimited uses.”

Gannon began the project to expand his green building contracting business to include manufacturing CEBs for use in an immense range of green building projects.

Dig SE’s CEBs are composed of North Carolina clay and follow the guidelines of “Cradle-to-Cradle” design (refering to design that “seeks to create systems that are not only efficient but also essentially waste free”) and manufacturing. The entire supply chain for CEBs takes place within 70+/- miles, from gleaning the clay at graded development sites in the Triangle area, to their final resting place in the homes of North Carolinians.

There are two kinds of blocks Dig southeast makes: stabilized, meaning mixed with cement to become weatherproof, and unstabilized, meant to be used indoors, or to be finished with a protective and aesthetically limitless layer of plaster. The machinery Gannon uses biodiesel-powered hydraulic press to compress the red clay into 7”x14” and 10”x14” blocks.

Each brick weighs about 20 lbs. That makes for great strength and substantial thermal and sound insulation. The blocks naturally repel insects, are flame and water resistant, and yes, they are bullet-proof as well.

CEBs make it possible to build a strong, well-insulated, energy efficient house using materials that can be created on-demand in any given community. Their uses are only limited by creativity, and have been used for a wide array of construction projects– think fences, flooring, walls, road paving, ovens, raised gardens, and dams, among others.

Making houses out of earth is not new. Bricks have been created for centuries. But today, more than ever, people are looking for simple and affordable alternatives for housing. Part of Gannon’s vision is to empower communities to build houses cheaply and using the greenest, healthiest building materials possible.

Gannon aims to lead workshops that teach people to create these blocks themselves using the same Carolina red clay, the same clay that we all have in our back yards here in the Piedmont.